Handmade Modern Furniture Features New Construction Techniques

Secreted away in a rural valley in upstate New York is a nondescript building, situated between a swath of trees and wild grassland, featuring a few free-range chickens. From the outside, there’s no indication of what’s going on inside: The design and creation of amazing modern furniture that’s in demand from coast to coast.

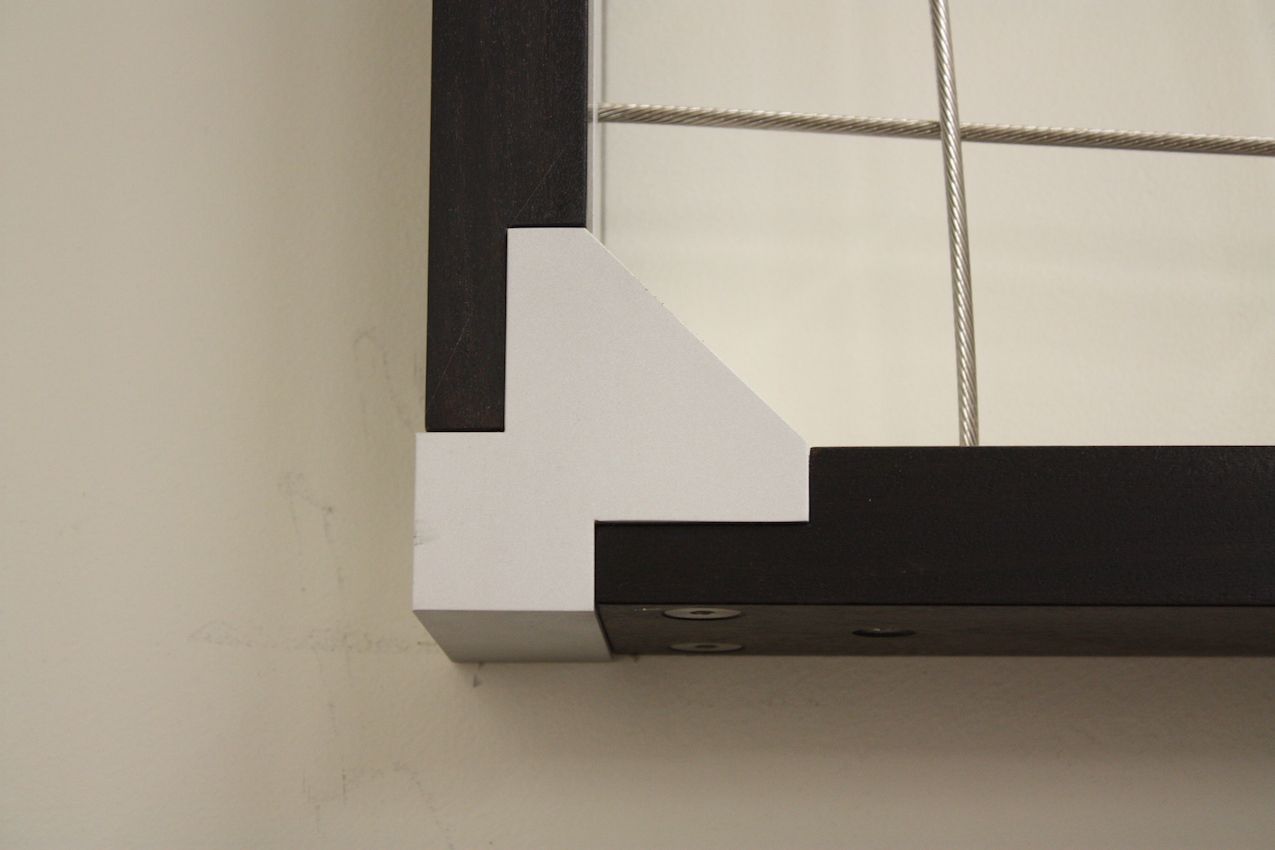

Furniture designer Peter Harrison combines modern materials with his own nontraditional joinery techniques to create exceptional limited production pieces that feature innovations of his own design such as aluminum brackets, draped cables and concrete components.

Homedit met Harrison at the Achitectural Digest Design Show 2016. We were immediately drawn to his work, particularly the Divergence Table and the Oahu table. The latter is one of the pieces in his newest line, featuring unique aluminum joinery. We had the privilege of visiting Harrison’s studio where we saw the work in progress and talked with him about his process, his designs, and how his work has evolved.

Homedit: Where do you get the inspiration for your pieces?

Harrison: Different pieces have different origins. The latest series came about because a client in Hawaii asked me to design a table that could easily be shipped to Hawaii, but not via freight service. I had to bring it with me on a flight, so I had to design something where the longest piece would still fit in standard luggage. The client’s apartment is on a high floor with an ocean view so it had to be light and airy. This led to my developing the aluminum brackets that hold pieces of wood. The bracketing is a whole new direction and is very different for me.

You get one little thing that pushes you off in some direction and then you follow that tangent.

Inside the studio there are several pieces that are clearly prototypes. “Before I make a piece I build a full-size mock-up. It allows me to compose in an entirely different way. If I encounter a new problem along the way, I can develop a new component to overcome it,” he explains

Homedit: You’re known for your unique joinery techniques. How did you decide to pursue this avenue?

Harrison: In 2003-2004, I was looking at the furniture I was making and asking myself what was limiting me. I decided that it was glue, and that if I could do it without glue, I could theoretically do it faster. There’s no downtime for pieces and finishing things flat is easier…Over time, the pieces have become more complex. The joinery has become so insanely complicated because it’s so different from traditional joinery techniques.

Harrison’s studio is divided into a woodworking area and a machine shop, both of which hold numerous vintage machines that have been refurbished and repurposed. “I have been buying pieces of machinery ever since my senior year in college. For me, more machines mean more creative freedom,” he explains.

After earning his BFA from the furniture program at the Rochester Institute of Technology, Harrison launched into making art and furniture full time, first in the Hudson Valley of New York and then in upstate, outside of Saratoga Springs.

“I like the older machines because they have a design to them. The newer ones are boxy. That said, the machines are a means to an end. Also, the used machines are cheap and well-built. I have rebuilt three-quarters of the machines in this room.”

In his machine room, Harrison has an amazing array of tools that allow him to cut and mill pieces to extremely precise measurements. He also has an incredible stock of of hardware.

One of the machines that Harrison acquired and rebuilt is this cutting table that he calls a very “sweet” machine. It came from the Hershey chocolate factory where it was originally used to cut printed materials. He converted the pica-based measurement tools on the machine to inch measurement tools, which are much more useful for a woodworker!

Homedit: How do you decide what form a new design will take?

Harrison: Most of my new designs are on spec, where I get to push my imagination. I look to sculpture, architecture, industrial objects, and materials for inspiration. Occasionally commissions push me in a new direction- as the Hawaii client. Most of the time my pieces develop around ideas strung together and I try not to miss taking abrupt turns as they come together.

The Nebula is actually made with 683 stainless steel cables tipped in Red Rubber.

Few images from saratogaphotographer.